Product Details:

Name: Metal Seats Ball ValveCatalog: Ball Valve

Certification: API6D-CE-ISO-API607

Contact Details:

Contact Person: Sales Manager Email: info@seekovalve.com

Email: info@seekovalve.com Tel: 0086-577-67312948

Tel: 0086-577-67312948 Fax: 0086-577-67312948

Fax: 0086-577-67312948

Seeko is one of the leading China Metal Seats Ball Valve manufacturers, welcome to inquiry Metal Seats Ball Valve from our factory.

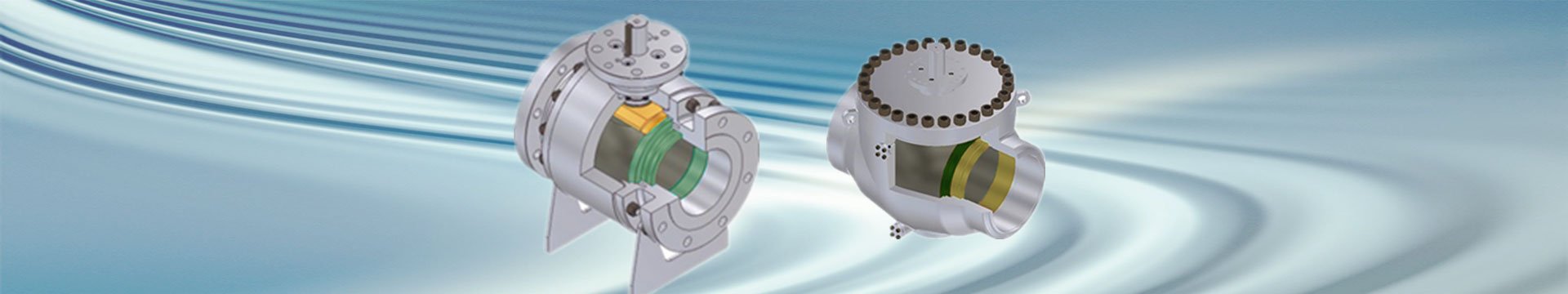

METAL SEAT BALL VALVE DESCRIPTION

Seeko metal seat ball valve has high tightness,it ensures the tightness via spring prepressing seat in case of low pressure.In case of high pressure,the tightness is secured via seat plunger effect.The key point is the original Seeko ball processing technical,which ensures the high precision of the ball(roundness).Advanced seat structure and high precision ball are the main factors of high tightness.At the same time,it extremely reduces operating torque.

The seat is of stellite alloy surface,and the ball sealing face is of three forms as hard chrome plating,vacuum coating and tunsten-titanium alloy and stellite alloy etc.It owns good friction-resistance and long life for pipeline delivery of mediums with various operating temperature,high friction dust,slurry and solid foreign matters mixture.

The most economical point lies in that Seeko metal to metal seat ball valve selects diffent seals according to different working condition.

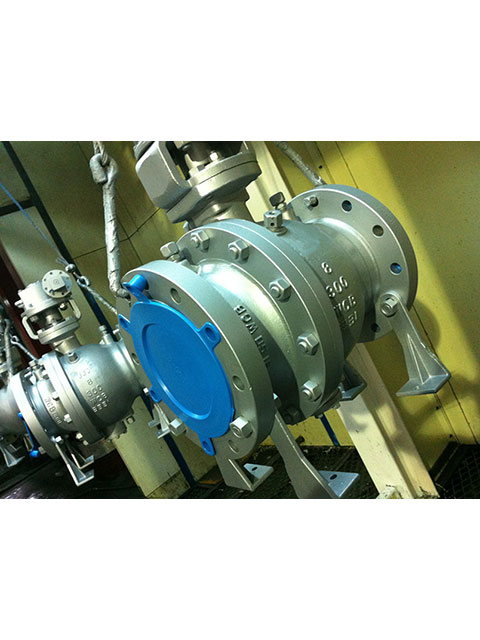

Seeko metal seat ball valve with high hadness metal seat is applicable for high temperature liquid,high friction dust,slurry,transmitter with impacting substances and solid mixtures etc.It is nearly applicable for all liquids.

PRODUCT RANGE

Size: 4” to 48”

Pressure Classes:

ASME 150# to 2500#

API6A3000 to 15000

Temperature Range: ‐196°C to 500°C

DESIGN FEATURES

Metal Seating Standard

Manual operated or Actuated Standard

Seats with satellite or TC coatng design On Request

Stem Extension with adjustable packing On Request

Self‐relieving Seats Standard

Mounting With Bracket for high temperature On Request

Double Piston Effect Seats On Request

Welded Pups On Request

Vent & Drain ports Standard

Wetted Areas Overlay On Request

MATERIAL SELECTION

BODY, CLOSURE

– CS (ASTM A105,A182 F11,A182 F22), LTCS (ASTM A350 LF2,LF3,12Mn)

– High strength LTCS (A694 F52, F60, F65)

– Austenitic SS (ASTM A182 F304, F316,F321)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Incoloy 825

– Monel

BODY SEALS / SEAT SEALS

– Viton A FKM O‐ring

– Viton GLT FKM O‐ring

– Viton AED FKM O‐ring

– HNBR AED O‐ring

– FFKM O‐ring

- Graphite Packing / Gaskets

TRIM (SEAT, BALL )

– CS (ASTM A105), LTCS (ASTM A350 LF2) + STL or TC

– High strength LTCS (A694 F52, F60, F65) + STL or TC

– AISI 410 Martensitic SS (ASTM A182 F6a) + STL or TC

– 17‐4 PH+ STL or TC

– Austenitic SS (ASTM A182 F304, F316) + STL or TC

– Duplex SS 22% Cr (ASTM A182 F51) + STL or TC

– Superduplex SS 25% Cr (ASTM A182 F53/F55) + STL or TC

– 6Mo SS (ASTM A182 F44) + STL or TC

– Inconel 625+ STL or TC

– Inconel 718+ STL or TC

– Incoloy 825+ STL or TC

– Monel+ STL or TC

STEM

– A182 F6A

– 17-4PH

– Duplex SS 22%(ASTM A182 F51)

–Superduplex SS 25% Cr (ASTM A182 F53/F55)

–Inconel 625

–Inconel 718

– Incoloy 825

– Monel

BOLTING

– ASTM A193 B7/B7M, ASTM A320 L7/L7M,

– A193/A320 B8/B8M

– UNS S31803, UNS S32760, ASTM A453‐GR.660

Recommended Related Products Feedback Form If you have any enquiry about quotation or cooperation, please feel free to email us at info@seekovalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.