Product Details:

Name: Cryogenic Ball ValveCatalog: Ball Valve

Certification: API6D-CE-ISO-API607

Contact Details:

Contact Person: Sales Manager Email: info@seekovalve.com

Email: info@seekovalve.com Tel: 0086-577-67312948

Tel: 0086-577-67312948 Fax: 0086-577-67312948

Fax: 0086-577-67312948

Seeko is one of the leading China Cryogenic Ball Valve manufacturers, welcome to inquiry Cryogenic Ball Valve from our factory.

VALVE DESCRIPTION

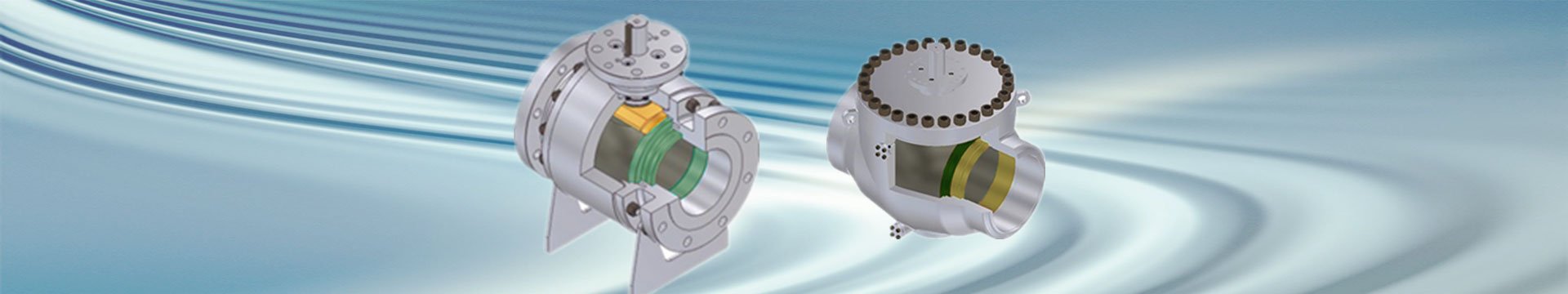

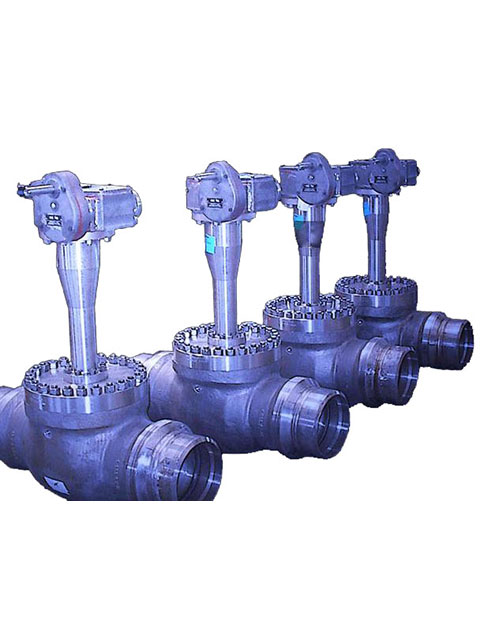

Seeko has specialised in Low Temperature and Cryogenic service to the extreme temperature of minus 196 Deg C, in accordance to the most stringent specifications. Seeko Ball Valves in cryogenic service are supplied with extended bonnet with a sufficient gas column length (vapour space) to keep the stem seals exposed only to vapour and not the cold liquid to ensure functional integrity. Suitable seals are selected considering the customer’s process indication. PTFE lip seal spring energised or KEL-F are commonly used.

BASIC CHARACTERISTICS

API 6D, API6Adesign

Full Bore and Reduced Bore design

Flanged or Welding Ends

Spring loaded floating seats

Bi-directional sealing

Anti blow‐out stem

Anti static device

Heavy duty bearings

Double Block & Bleed design

Fire safe design

NACE MR 0175

PRODUCT RANGE

Sizes :

From 1/2″ up to 48″

Classes:

ANSI 150-300-600-900-1500-2500

API 2000-3000-5000-10000-15000

Materials:

Low Temperature Carbon Steel, Stainless Steel.

DESIGN FEATURE

Soft Seating Standard

Manual operated or Actuated Standard

Metal Seating On Request

Stem Extension On Request

Self‐relieving Seats Standard

Extended Bonnet On Request

Double Piston Effect Seats On Request

Welded Pups On Request

Vent & Drain ports Standard

Sealing Areas Overlay On Request

Emergency sealant injection On Request

Wetted Areas Overlay On Request

MATERIAL SELECTION

FORGED BODY, BONNET, PUPS

– CS (ASTM A105,A182 F11,A182 F22), LTCS (ASTM A350 LF2,LF3,12Mn)

– High strength LTCS (A694 F52, F60, F65)

– Austenitic SS (ASTM A182 F304, F316,F321)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Incoloy 825

– Monel

–Wetted or Sealing Areas Overlay On Request

CAST BODY, BONNET, PUPS

– CS (ASTM A216 WCB,WCC,WC6,WC9), LTCS (ASTM A352 LCB,LCC,LC1,LC2,LC3)

– Austenitic SS304 (ASTM A351 CF8), SS316 (ASTM A351 CF8M),SS304L(ASTM A351 CF3),SS316L(ASTM A351 CF3M)

– Duplex SS (ASTM A8904A,5A,6A)

– Alloy 625(UNS N06625)

– Alloy 825(UNS N08825)

– Special alloy material(CW6MC)

–Wetted or Sealing Areas Overlay On Request

BODY SEALS / SEAT SEALS

– Viton A FKM O‐ring

– Viton GLT FKM O‐ring

– Viton AED FKM O‐ring

– HNBR AED O‐ring

– FFKM O‐ring

– PTFE + ELGILOY Lip‐Seals

– Graphite Packing / Gaskets

TRIM (SEAT, BALL and STEM)

– CS (ASTM A105), LTCS (ASTM A350 LF2,LF3,12Mn) + ENP0.003”

– High strength LTCS (A694 F52, F60, F65) + ENP0.003”

– AISI 410 Martensitic SS (ASTM A182 F6a)

– 17-4 PH

– Austenitic SS (ASTM A182 F304, F316)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Inconel 718

– Incoloy 825

– Monel

SEAT INSERT

– Viton A/GLT/AED FKM (only EB model)

– HNBR (only EB model)

– PTFE / RPTFE

– Nylon / DEVLON V

– PCTFE / KEL‐F

– PEEK

– METAL with either TUNGSTEN CARBIDE or

– CHROMIUM CARBIDE COATING (0.15 mmmin. thk.)

BOLTING

– ASTM A193 B7/B7M, ASTM A320 L7/L7M,

– A193/A320 B8/B8M

– UNS S31803, UNS S32760, ASTM A453‐GR.660

Recommended Related Products Feedback Form If you have any enquiry about quotation or cooperation, please feel free to email us at info@seekovalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.