Product Details:

Name: Forged Trunnion Ball ValveCatalog: Ball Valve

Certification: API6D-CE-ISO-API607

Contact Details:

Contact Person: Sales Manager Email: info@seekovalve.com

Email: info@seekovalve.com Tel: 0086-577-67312948

Tel: 0086-577-67312948 Fax: 0086-577-67312948

Fax: 0086-577-67312948

Seeko is one of the leading China Forged Trunnion Ball Valve manufacturers, welcome to inquiry Forged Trunnion Ball Valve from our factory.

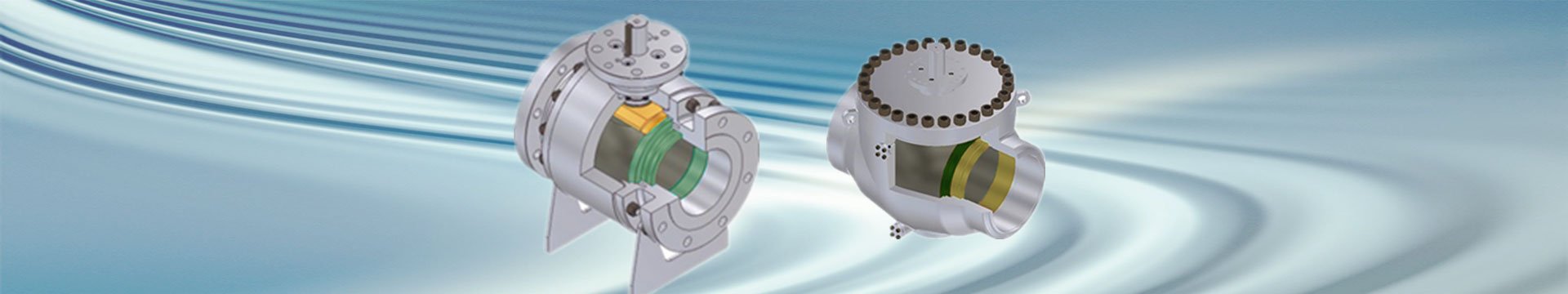

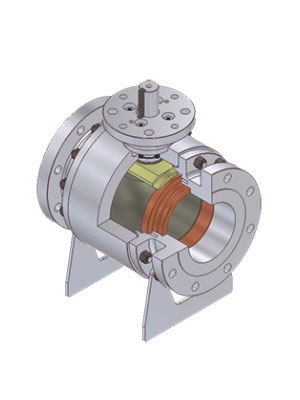

INTERNAL TRUNNION BALL VALVE DESCRIPTION

The ball of trunnion mounted configuration is supported by bearing plates hold by the end adaptors. In such a way the pressure loads are transferred to the valve body granting a smooth rotation of the ball with low torque levels and reduced seat seal wear.

SEEKO Trunnion Mounted Bolted Body Side‐Entry Ball Valves represent the

basic design standard.

They are manufactured in a wide range of sizes and pressure classes typically

from forgings.

EXTERNAL TRUNNION BALL VALVE DESCRIPTION

The ball of trunnion mounted configuration

is supported by external trunnions bolted to the body.

In such a way the pressure loads are transferred to the valve body granting a

smooth rotation of the ball with low torque levels and reduced seat seal

wear.

BASIC CHARACTERISTICS

API 6D, API6Adesign

Full Bore and Reduced Bore design

Flanged or Welding Ends

Spring loaded floating seats

Bi‐directional sealing

Anti blow‐out stem

Anti static device

Heavy duty bearings

Double Block & Bleed design

Fire safe design

PRODUCT RANGE

Size: 4” to 48”

Pressure Classes:

ASME 150# to 2500#

API6A3000 to 15000

Temperature Range: ‐196°C to 450°C

DESIGN FEATURES

Soft Seating Standard

Manual operated or Actuated Standard

Seats with Delta Ring design On Request

Stem Extension On Request

Self‐relieving Seats Standard

Extended Bonnet On Request

Double Piston Effect Seats On Request

Welded Pups On Request

Vent & Drain ports Standard

Sealing Areas Overlay On Request

Emergency sealant injection On Request

Wetted Areas Overlay On Request

MATERIAL SELECTION

BODY, CLOSURE

– CS (ASTM A105,A182 F11,A182 F22), LTCS (ASTM A350 LF2,LF3,12Mn)

– High strength LTCS (A694 F52, F60, F65)

– Austenitic SS (ASTM A182 F304, F316,F321)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Incoloy 825

– Monel

BODY SEALS / SEAT SEALS

– Viton A FKM O‐ring

– Viton GLT FKM O‐ring

– Viton AED FKM O‐ring

– HNBR AED O‐ring

– FFKM O‐ring

– PTFE + ELGILOY Lip‐Seals

– Graphite Packing / Gaskets

TRIM (SEAT, BALL and STEM)

– CS (ASTM A105), LTCS (ASTM A350 LF2) + ENP0.003”or overlay on request

– High strength LTCS (A694 F52, F60, F65) + ENP0.003”

– AISI 410 Martensitic SS (ASTM A182 F6a)

– 17-4 PH

– Austenitic SS (ASTM A182 F304, F316)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Inconel 718

– Incoloy 825

– Monel

SEAT INSERT

– Delta Ring with O Ring design on request

– PTFE / RPTFE

– Nylon / DEVLON V

– PCTFE / KEL-F

– PEEK

– Stellite or Tungsten CARBIDE COATING (0.15 mmmin. thk.)

BOLTING

– ASTM A193 B7/B7M, ASTM A320 L7/L7M,

– A193/A320 B8/B8M

– UNS S31803, UNS S32760, ASTM A453‐GR.660

Recommended Related Products Feedback Form If you have any enquiry about quotation or cooperation, please feel free to email us at info@seekovalve.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.