Product Details:

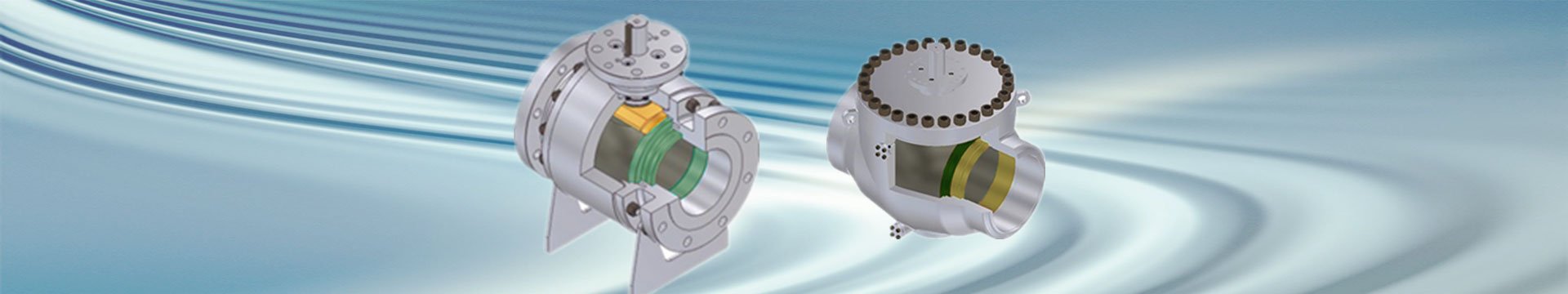

Name: Plug ValveCatalog: Plug Valve

Certification: API6D-CE-ISO-API607

Contact Details:

Contact Person: Sales Manager Email: info@seekovalve.com

Email: info@seekovalve.com Tel: 0086-577-67312948

Tel: 0086-577-67312948 Fax: 0086-577-67312948

Fax: 0086-577-67312948

Seeko is one of the leading China Plug Valve manufacturers, welcome to inquiry Plug Valve from our factory.

Seeko offers a wide range of plugs in lubricated, seeled, orbit and eccentric type. All Plug Valves manufactured by our company are from high quality cast carbon steel. Seeko Plug Valves are 90 degree action from open to close, protected seats, positive shut off, simple in line maintenance, minimum flow resistance, simple construction, and finally, rugged construction ensuring long life. Seeko Plug valves can be operated manually by wrench, Hand wheel through gear box, or quarter-turn actuator driven pneumatically or electrically. Our company is renowned as one amidst the reliable Plug Valves Manufacturers and Suppliers.

BASIC CHARACTERISTICS

API 6D design

Full Bore and Reduced Bore design

Flanged or Welding Ends

Bi-directional sealing

Double Block & Bleed design

NACE MR 0175

Pressure balanced Lubricated plug valve

Double Block And Bleed Twin seal Plug Valve

Eccentric Plug Valve

PRODUCT RANGE

Size: 2” to 12”

Pressure Classes:

ASME 150# to 600#

Temperature Range: ‐46°C to 450°C

DESIGN FEATURES

Soft Seating Standard

Manual operated or Actuated Standard

Stem Extension On Request

Self‐relieving Seats Standard

Extended Bonnet On Request

Welded Pups On Request

Vent & Drain ports Standard

Sealing Areas Overlay On Request

Emergency sealant injection On Request

Wetted Areas Overlay On Request

MATERIAL SELECTION

BODY, CLOSURE

– CS (ASTM A216 WCB,WCC,WC6,WC9), LTCS (ASTM A352 LCB,LCC,LC1,LC2,LC3)

– Austenitic SS304 (ASTM A351 CF8), SS316 (ASTM A351 CF8M),SS304L(ASTM A351 CF3),SS316L(ASTM A351 CF3M)

– Duplex SS (ASTM A8904A,5A,6A)

– Alloy 625(UNS N06625)

– Alloy 825(UNS N08825)

– Special alloy material(CW6MC)

TRIM MATERIAL

– CS (ASTM A105), LTCS (ASTM A350 LF2) + ENP0.003”

– High strength LTCS (A694 F52, F60, F65) + ENP0.003”

– AISI 410 Martensitic SS (ASTM A182 F6a)

– 17‐4 PH

– Austenitic SS (ASTM A182 F304, F316)

– Duplex SS 22% Cr (ASTM A182 F51)

– Superduplex SS 25% Cr (ASTM A182 F53/F55)

– 6Mo SS (ASTM A182 F44)

– Inconel 625

– Inconel 718

– Incoloy 825

– Monel